NT Group - Industrial AI & 3D - PoC

The Client and Their Needs

NT Group is an international group specializing in the design, engineering, and production of steel components, structures, and equipment for the maritime, agricultural, and industrial sectors. The group includes Novatech, with headquarters in Aalborg, Denmark, and a production facility in Orzesze, Poland. NT Group employs around 350 people of 8 nationalities and operates in Denmark, Poland, and Finland. The company puts strong focus on in-house design and product development, working closely with clients from concept to implementation.

Industrial AI - Artificial Intelligence for Industry

Industrial AI is the practical use of machine learning in industrial processes - from production to maintenance. Its goal is to automate tasks, predict issues, and support decision-making. For NT Group, Industrial AI supports spare parts handling and service operations. Hatimeria implemented a scalable, automated AI solution that’s already delivering results as part of a proof-of-concept phase.

AI Engineering

The AI component of this Proof of Concept was developed in collaboration with Tanner Lab – a company founded by our long-term partner, Thomas Tanner. Based in Switzerland, Tanner Lab focuses on digitalisation and automation by building tailored solutions that solve real-world problems. Tanner Lab used the power of AI to solve a common challenge. For this project, the team focused on resolving a specific issue: identifying the correct technical documentation from just a customer-taken photo of a spare part. Together, we built a proof of concept using Retrieval-Augmented Generation (RAG) and the latest multimodal AI models trained on both images and text.Read more here.

What is RAG?

Retrieval-Augmented Generation (RAG) is an AI approach that helps find the right answer quickly. It first looks for the most relevant data, then uses AI to generate a clear, useful response based on that information. It’s a smart way to solve problems like recognizing spare parts or matching the right documents - especially when time and accuracy matter.

On-site Workshops. Understanding the Real Needs

The Hatimeria team visited NT Group’s production site in Orzesze multiple times to gain hands-on insight into the processes, meet the team, and identify the client's key challenges. Direct talks with employees from different departments helped us match the technology with real-life needs and industry specifics.

Hatimeria team visiting NT Group's site in Orzesze

Business Challenges

NT Group faces a growing number of service requests without the ability to quickly scale its support team. Key issues include: No single person knows all machine models.

- Different model versions and modifications make part identification difficult.

- Outdated PDF catalogs are hard to use and not updated.

- The parts team spends too much time identifying components, leading to errors.

- Staff must manually compare parts with technical drawings, which is inefficient and time-consuming.

- Investors expect a digital, automated, and all-in-one tool for spare parts sales and service.

Existing Tech Environment

NT Group’s design team uses SOLIDWORKS, a leading 3D CAD tool provided by SOLIDEXPERT, a top CAD/CAE/CAM/PDM/PLM software provider. Hatimeria also uses SOLIDWORKS under an official commercial license and maintains an active partnership with SOLIDEXPERT, ensuring stability, regular updates, and full technical support. SOLIDWORKS supports 3D modeling, technical documentation, and functional simulations-speeding up prototyping and reducing construction errors. Engineering teams can easily create and update precise models.

Design data is then transferred to Roima/Aton PLM, which manages BOM structures and component relationships-ensuring consistency across R&D and production.

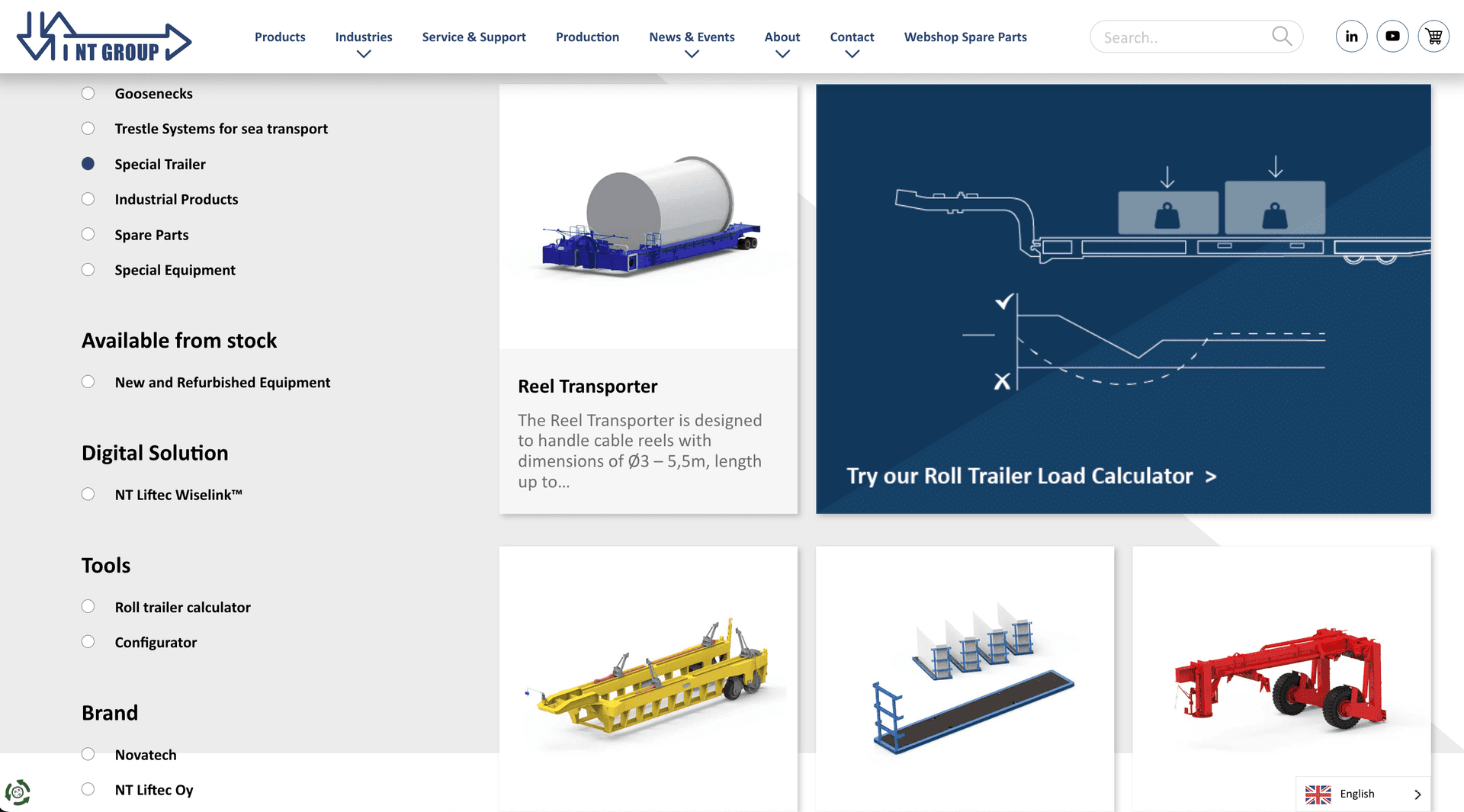

Our Solution – Proof of Concept - 3D Configurator + AI Chatbot by Hatimeria

Hatimeria developed and implemented an innovative 3D configurator with an AI chatbot, integrated with the client's systems. This proof of concept demonstrates how technology can transform part identification and ordering.

What Hatimeria did:

- Ran workshops and site visits to understand service processes and identification challenges.

- Designed the architecture of the digital solution.

- Built an interactive 3D configurator for visual machine navigation.

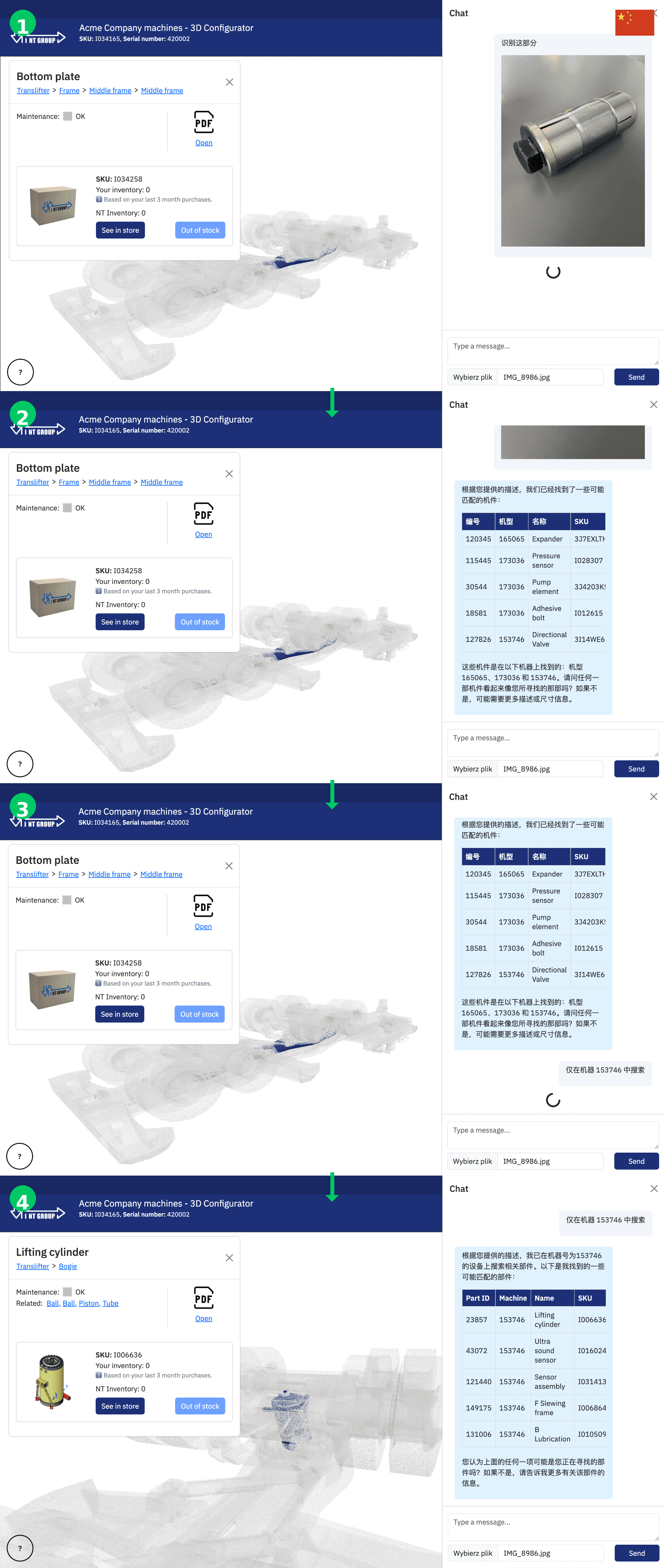

- Created an AI chatbot for service support and part recognition using technical data and images.

- Integrated the system with the client’s existing IT tools to ensure data security and consistency.

Key Features:

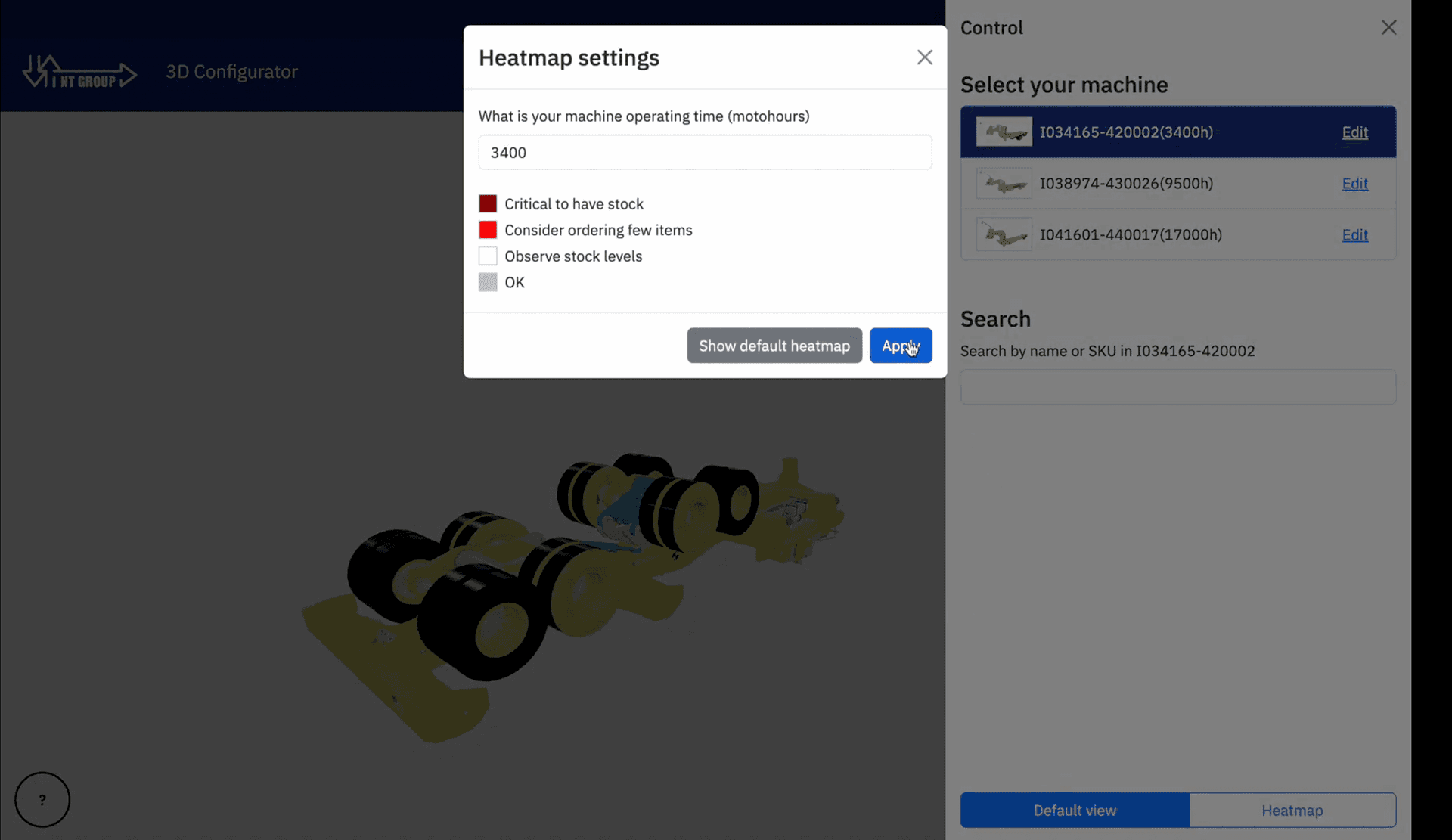

- Login and Machine Access: Employees log in to see machines used by their company. Machines can be identified by serial number or visually through a 3D model.

- Part Identification: Users upload a photo or enter technical data. AI analyzes the input, identifies the part, and asks follow-up questions if needed.

- Service Kit Suggestions: Based on machine operating hours, the chatbot recommends ready-made service kits tailored to the specific model and its usage.

Heatmap View: The 3D configurator highlights parts that require service.

- Heatmap View: The 3D configurator highlights parts that require service, based on usage data and failure patterns.

- Interactive 3D Navigation: In addition to AI chat-based identification, users can explore the entire machine structure via a tree-view interface. They can click directly on parts within the 3D model to view part names, details, and related documentation.

- Add to Cart Functionality: Identified parts can be immediately added to the shopping cart directly from the 3D view or chat interface.

- Full E-commerce Integration: The system is fully integrated with the client's online store, enabling real-time pricing, stock checking, and easy ordering.

- 24/7 Availability: The system runs continuously, allowing users to request and order parts anytime.

- Global Compatibility: The AI understands messages in any language, works across all time zones, and supports all metric systems.

Tech Stack:

Frontend: React, Vite, three.js

Backend & AI: Python, LanceDB, FastAPI, Torch, LLM models: Mistral, LLaVa

Supporting Technologies:

- LiDAR scanning (e.g., Kiri Engine)

- Integration with SOLIDWORKS CAD

- Integration with Roima / Aton PLM

From Physical Part to 3D Model

1. Part Photo – shows the real part on the machine or separately

2. LiDAR Scan – precise 3D scan of the part’s shape and dimensions

3. Configurator Model – interactive 3D model that can be rotated, zoomed, and easily matched for online ordering

From a real-life part to a 3D model - created by Hatimeria

Expected Results and Benefits

- Faster service response – from hours or days to just minutes, improving customer satisfaction.

- Fewer order errors – AI verification and suggestions reduce mistakes.

- Less workload for support teams – repetitive requests handled automatically.

- Better user experience – simple and intuitive self-service part ordering.

- Higher operational efficiency – more requests handled without hiring more staff.

- Scalable solution – architecture ready for expansion and increased usage.

A New Level of Service Support

AI can understand messages like: “I need a service kit after 8000 hours of operation.”

It matches the components and adds them to the cart with one click.

It works in any language – regardless of user location

Sample conversations with an AI chatbot in Spanish

Sample conversations with an AI chatbot in Chinese

Summary

The implementation of Hatimeria’s 3D Configurator with AI:

-

Boosts customer support efficiency

-

Minimizes order errors

-

Reduces staff workload

-

Handles more service requests without scaling the team

-

Improves data quality and information flow

-

Prepares the company for future digital growth

This is a practical example of how Industrial AI can revolutionize the industry and bring real business value.

Want to see it in action?

Let’s explore how AI can solve your after-sales challenges. Contact Hatimeria and book a discovery workshop.

Would you like to create something similar and innovate your ecommerce project with Hatimeria?

Our Latest Thinking