By Julia , May 25, 2025 · 9 min read

How We Used AI, CAD, and LiDAR to Automate Spare Parts Identification in Heavy Industry

The Digital Gap in Industrial Customer Support

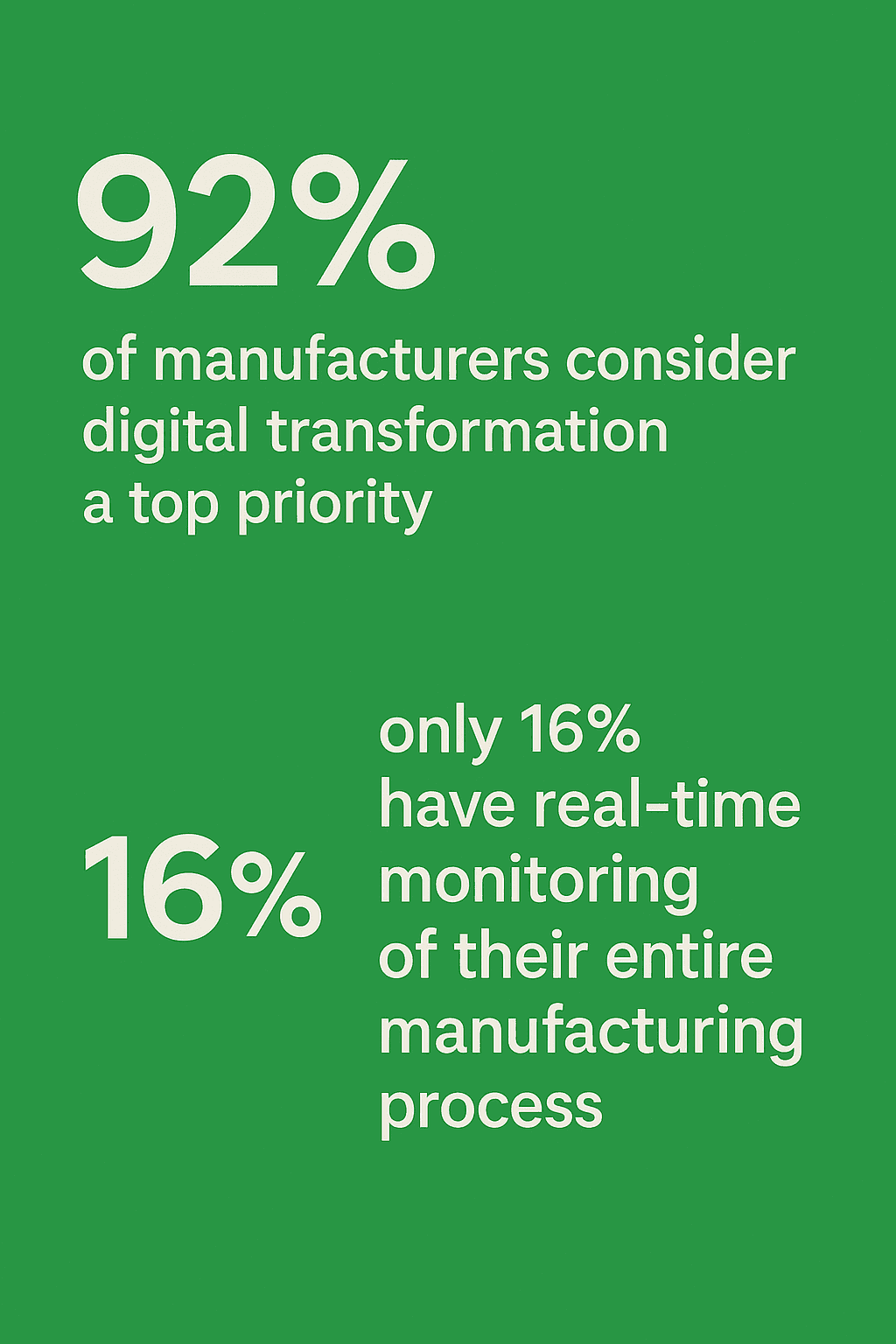

Despite advances in technology, many industrial companies remain behind in digital transformation - especially in customer support. Most manufacturers still rely heavily on traditional channels like phone and email, which leads to slow response times and fragmented support experiences. According to a recent industry analysis, while 92% of manufacturers consider digital transformation a top priority, only 16% have real-time monitoring of their entire manufacturing process, and many still struggle to connect digital tools with day-to-day operations. This lack of integration means customer service teams are often overloaded, and customers face delays and inefficiencies due to outdated, manual workflows. As a result, the industrial sector continues to face significant barriers in delivering fast, seamless, and scalable support.

1. The Problem We Solved

Identifying spare parts in industrial machines used to be a slow and frustrating process. Variants, outdated PDFs, and missing documentation often cause costly delays. Support teams are overwhelmed, and manual workflows lead to frequent errors and unnecessary downtime. We prepared a modern app enhanced by AI that eliminates these obstacles, streamlining part identification and empowering both customers and support staff.

2. How we connected CAD model with browser

Our first step was to connect the world of CAD systems with the world of the user. It was necessary to display 3D models in the browser so that the client could view machine details, search for the appropriate part based on SKU or name, and verify it by its location in the machine. For this purpose, we used three.js, an advanced JavaScript library for displaying 3D models in the browser. three.js allows for:

-

Creating interactive 3D scenes where you can place objects, cameras, lights, and animations.

-

Easily adding and manipulating ready-made geometric shapes as well as importing 3D models from various file formats such as OBJ, FBX, GLTF, or Collada.

-

Realistic lighting and shading, support for many types of lights and materials, which enables advanced visual effects.

-

Rendering 3D graphics using WebGL, which ensures that projects run smoothly and efficiently on most modern browsers.

-

Animating objects, including support for bone systems, morph targets (geometry changes), transformations, and other model properties.

-

Adding interactivity - the user can click, drag, zoom, and interact with 3D objects in the scene.

In our proof of concept, we exported the model from SOLIDWORKS to the .glb format, which is supported by three.js. We built our application in React, which allowed us to create a modern and user-friendly interface. At its center is an interactive 3D model of the machine. The user can rotate it, change the tilt angle, and zoom. When an element is clicked, the selected part is highlighted along with information and the option to add it to the cart. Using the BOM (Bill of Materials), we mapped elements in the 3D model to products available in our store. In this way, we connected CAD and ecommerce.

3. How We Used AI?

3D models in the industrial sector can be very complex, and simply enabling the user to view them in the browser does not necessarily make it easier to purchase the right part. Technical knowledge about the product, spare parts, and the specific machine is also required. Typically, the process of purchasing parts requires direct contact with the service team and an exchange of emails or phone calls. This is where AI can help. AI systems are able to use a vast amount of data and, based on it, provide the user with a reliable answer in a very short time. Such a volume of data cannot be processed by a human-certainly not in such a short time.

In our case, we can use AI for faster part identification. The user does not have to (although they still can, as all these options remain available in our interface) search for a part by name, SKU, or try to locate it in the machine. Instead, they can take a photo, scan, or simply try to describe the sought part in words. The information they have can then be provided to the AI chat-which, based on its knowledge, will identify the desired part. The chat may not always identify the part correctly at first - sometimes it will ask for more information, and in most cases, it will initially return a list of parts that best match the query. The user can then verify the suggestions received and either finish their search or provide additional information.

Additionally, the chat can provide technical information about the part or machine-for example, installation methods or maintenance guidelines. The chat operates 24/7 and can respond in the user’s language - whether it’s English, Spanish, or Mandarin.

4. Advanced AI: RAG

To ensure our system has the most up-to-date data and can respond with maximum accuracy (without risking hallucinations), we needed to ensure the model actually uses knowledge from our product database, parts catalog, and technical documentation. For this purpose, we built a RAG system. RAG (Retrieval-Augmented Generation) is a hybrid AI technique combining multiple stages:

1. Information Retrieval: When a user query is received, the system searches external data sources (databases, documents, websites, PDFs) to find the most relevant passages or documents related to the question. This search often uses advanced semantic methods, such as vector database queries.

2. Prompt Augmentation: The retrieved information is appended to the user’s original query, creating an enriched context for the language model. This ensures the model receives both the question and fresh, precise source data.

3. Answer Generation: The language model (e.g., GPT-4, LLaMA, Mistral) generates a response based on both its training knowledge and the newly retrieved information. The result is a more accurate, reliable, and up-to-date answer, often with cited sources.

In our proof of concept, part information is stored in LanceDB, a vector database. Product images, names, and descriptions are stored as embeddings-numeric, multidimensional representations of data (words, sentences, documents, images) that capture their meaning and context. Each embedding is a point in multidimensional space, where semantically similar data points cluster closer together. We also store metadata (e.g., product SKUs) in the database.

When a user query arrives:

- We collect all provided input (text, images, etc.).

- Search our vector database to identify parts best matching the query.

- Use the LLM to generate a response: either return identified parts or request additional details if needed.

AI Engineering

The AI part of this project was developed together with Tanner Lab, founded by our long-time partner Thomas Tanner. Based in Switzerland, Tanner Lab is a software consultancy specialized in digitalization and automation, web application development, and AI engineering.

In this case, they used the power of AI to tackle a common challenge: how to identify the right technical documentation from a simple photo of a spare part taken by a customer. The team built a proof of concept using Retrieval-Augmented Generation (RAG) and advanced multimodal models trained on both text and images. This solution doesn’t just show what's possible with AI - it brings real business value by speeding up support, reducing manual work, and making the whole spare parts process faster and more reliable. Read more here.

5. 3D + LiDAR Scanning: Bringing Physical Machines into the System

Beyond searching based on standard photos, we can also use LiDAR scans for part identification. The LiDAR system (Light Detection and Ranging) is an advanced remote sensing technology used to measure distances with precision and create detailed 3D models of environments using laser light. LiDAR operates independently of lighting conditions (e.g., at night), achieves extremely high resolution and measurement accuracy (down to single millimeters), and allows for fast, efficient scanning of large areas-generating millions of points per second.

Users can identify parts even without documentation using LiDAR scanning:

- Use an iPhone (from 12) or iPad with LiDAR.

- Scan the part using a mobile app like Kiri Engine.

- Upload the model → AI matches it to existing 3D geometry.

- This is especially useful for legacy machines or for technicians working in the field. This brings real-world objects directly into the AI system, fast and accurately.

Example screenshots of a 3D scan from the LiDAR app – taken with an iPhone.

6. How the Full System Works

How do all these parts of the system connect with each other, and what does using it look like in practice?

- Users log in and select a machine.

- They can view the machine and manually look for a part

- Or they can talk with AI chat to identify the part:

a) They can upload a photo, LiDAR scan or just provide any information they have.

b) AI identifies the part based on provided information, returns a list of matching parts and asks follow-up questions if needed.

c) The user can verify matching parts returned by the chat and add it (or them) to the cart

- If needed, users can ask chat about service tips.

a) AI chat returns info based on data gathered in documentation and service information

7. Tech Stack

- Frontend: React + three.js (3D visualization)

AI Backend: Python (FastAPI)

Vector database: LanceDB

LLM model: Mistral

- Integrations:

- SOLIDWORKS (CAD models)

- Roima / Aton PLM (product structures, versions)

- LiDAR support: via Kiri Engine scans from iOS devices

8. Results - Proof of concept

Our app transforms the process of part identification from manual chaos to automated precision in just minutes. Customers can now handle service tasks independently, without waiting for support teams. For businesses, the system is fully scalable-easily expanding to cover more products, markets, and languages. The result is faster service, empowered users, and a solution ready to grow with your needs.

Curious how it works in practice? Check the detailed story:

9. Why This AI Is Different

Unlike generic AI tools, our system is powered by real industrial data and tailored workflows-not broad, one-size-fits-all models. No Guesswork, Just Results:

-

Combines LLMs with RAG to ground answers in your exact product data, documentation, and CAD/PLM systems.

-

Leverages LiDAR scans for millimeter-accurate 3D matching-no approximations.

Designed for Real-World Applications:

- Integrates seamlessly with tools like CAD and PLM, fitting into existing workflows. This isn’t theoretical AI-it’s practical, precise, and purpose-built for industrial challenges.

10. Want to See It?

Book a technical demo with Hatimeria. We’ll show you how LLama, RAG, and 3D scanning with just an iPhone can change your spare parts operations. Learn more! Schedule your discovery call today.

Would you like to innovate your ecommerce project with Hatimeria?

A mountain lover and code climber. She can reach any peak and conquer any coding challenge. Loves ramen, reading books and watching TV series. Wins every Hatimeria competition.

Read more Julia's articles